Filters

Color

Density

Effect

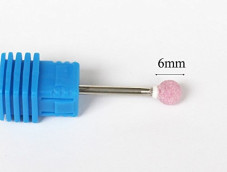

A corundum nozzle is a specially designed tool that is widely used in various industrial applications. It is a type of hard and abrasive ceramic nozzle that is made from corundum, a mineral that is typically found in rocks and soils. Corundum is one of the hardest minerals on earth, with a hardness rating of nine on the Mohs scale, making it highly resistant to wear, corrosion, and high temperatures.

Corundum nozzles are commonly used in milling cutters where they are used to control the flow of abrasive fluids, such as water, oil, or air. They are also used in nail extensions to accurately deposit acrylic or gel onto nails, making it easier to achieve a precise and even application. Additionally, corundum nozzles are used in various other industrial applications, such as metalworking and cutting, as well as in the production of ceramics and glass.

One of the main benefits of using a corundum nozzle is their ability to resist wear and corrosion. This means that they have a longer lifespan than many other types of nozzles and require less frequent replacement. They are also resistant to high temperatures, which makes them suitable for use in applications where materials are being heated or processed at high temperatures.

In addition, corundum nozzles are highly resistant to chemically aggressive fluids, such as acids, alkalis, and solvents, making them ideal for use in aggressive chemical environments. This makes corundum nozzles a popular choice in chemical processing and industrial manufacturing.

When it comes to nail extensions, corundum nozzles provide precise and even application while protecting the natural nail from damage. They can also be used to create intricate nail designs.

In milling cutters, corundum nozzles are often used in combination with abrasive fluids, such as water, that help to break down the material being cut. The nozzle helps to direct the flow of the fluid, while the corundum material ensures that the nozzle itself will not wear down easily, even if it comes into direct contact with the material being cut.

Finally, it's important to note that corundum nozzles come in a range of sizes and shapes, which allows them to be used in a variety of applications. This versatility, combined with their high durability and resistance to wear, make corundum nozzles an excellent choice for a wide variety of industries and applications.