Filters

Color

Density

Effect

Nozzles, caps, and abrasive materials play a critical role in various industries, such as milling, carpentry, and cosmetics. These tools help enhance accuracy, efficiency, and precision in manufacturing and production processes.

One of the prime uses of nozzles is in milling cutters, which are used to shape or carve materials such as metal, wood, and plastics. The use of nozzles helps to direct the flow of coolant or lubricant to the cutting area, which prevents the material from overheating and warping. The nozzles are also designed to reduce the amount of dust and debris created during the milling process.

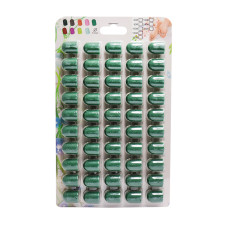

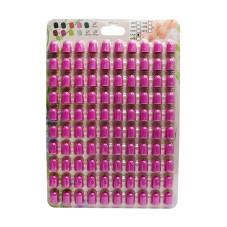

Nail extensions are a popular cosmetic application where nozzles are used. Nail extensions are plastic or acrylic material that is applied on natural nails to add length and shape to nails. The use of nozzle helps to control the flow of the adhesive into the nail bed and around the nail extensions to ensure a proper application. Furthermore, it helps eliminate bubbles and air pockets, leading to a smooth and flawless finish.

Abrasive materials like caps are used in various industries like metalworking, woodworking, and surface finishing. They are made from abrasive particles like aluminum oxide, diamond, and silicon carbide, and they are used to remove unwanted materials, rust, coatings, or finish surfaces. Caps come in various shapes, sizes, and grits to address specific surface preparation requirements, and they are ideal for removing material without damaging the underlying surface.

In conclusion, nozzles, caps, and abrasive materials are essential tools in many manufacturing and production processes. They are pivotal in enhancing precision, efficiency, accuracy, and safety while reducing waste and downtime. Whether it is in milling cutters, nail extensions, or surface finishing, nozzles, caps, and abrasive materials play a critical role in achieving optimal results.